Danfoss' new DST P070 pressure sensor promises a compact, sustainable solution for the heat pump market – but will it survive the refrigerant onslaught?

The push for electrified heating continues, with heat pumps leading the charge to replace fossil fuels. The European Union's REPowerEU initiative, for example, aims to double heat pump installation rates every four years, targeting 60 million installations by 2030. Danfoss, keen to grab a slice of the action, is pushing its new DST P070 pressure sensor, designed for compact HVAC applications.

Iro Dragoumi, Segment Manager for HVAC&R at Danfoss Sensing Solutions, reckons, "The DST P070 addresses this challenge by offering reliable pressure-sensing technology in a compact design."

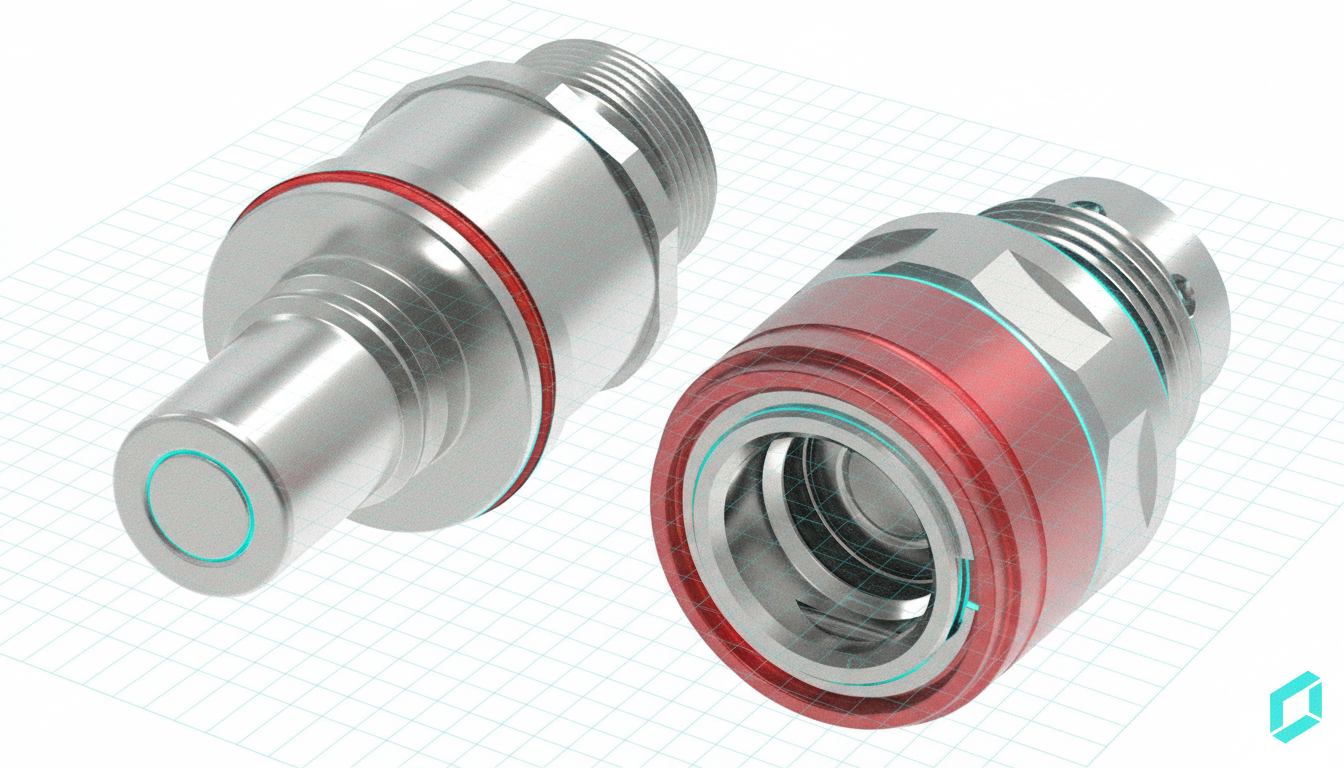

The DST P070 uses backside MEMS technology, supposedly optimising its size and weight.

Katharina Löhden, Product Manager for Pressure Sensors at Danfoss Sensing Solutions, claims it's ideal for tight spots: "The DST P070 offers the shortest solder tube length on the market, a small body sensor, and a single-brazing point, facilitating easier installation in confined spaces." Apparently, its lightweight design also reduces the need for vibration support.

Tight Squeeze

The sensor's bi-metal solder tube – copper and stainless steel – is claimed to eliminate the need for cooling during soldering. Danfoss reckons this "shortens installation time and makes the entire process easier for the installer."

They also state that superior welds and precision brazing lower heat transfer, potentially extending the sensor’s life.

No HVAC component is complete without claims of refrigerant compatibility, of course. Danfoss says the DST P070 is compatible with A1, A2L, and A3 refrigerants, including R290 and R1234ze. Validation tests supposedly confirm its resistance to helium leakage, overpressure, thermal stress, and vibration. The sensor is also ISO 14903 design tested, ATEX Zone 2, and HazLoc compliant.

Germany Steps Up

To meet demand, Danfoss has expanded production with a new automated line in Minden, Germany. This facility sources 70% of its materials locally within the EU and offers full parts traceability. The site is compliant with ISO 14001, ISO 9001, and IATF 16949 standards, aligning with Danfoss' sustainability commitments – aiming for carbon neutrality by 2030.

Danfoss also points to other recent news: Danfoss BOCK HGX56 Featured At RETA 2025, Danfoss HVAC Tech At SuperComputing 2025, Danfoss & ANEO Retail: Nordic Energy Optimization, and Danfoss Strengthens US-EU Economic Partnerships.

The DST P070's production process apparently emphasises sustainability. The sensor contains more than 50% recycled stainless steel and boasts a reduced carbon footprint due to its compact design. They've even introduced pulp tray packaging, cutting CO2 emissions and transport volume by 50%.

All adding up to what Iro Dragoumi calls "a sensor designed for top-quality HVAC applications and one that supports a sustainable manufacturing process."

Time Will Tell

Will this sensor truly revolutionise heat pump installations? Only time – and rigorous field testing – will reveal the truth behind the marketing hype.