Delta Controls is boasting about its new Panasonic 'pick and place' machines that’ll supposedly assemble boards four times faster; colour me sceptical.

The Canadian manufacturer of building automation systems trumpets an upgrade to its manufacturing. Two Panasonic 'pick and place' machines and a solder reflow oven, no less. This investment, they say, means boards assembled four times faster than before.

In a recent announcement, Delta Controls highlights the new kit in a video featuring Marcio Lotierzo, Director of Manufacturing. Lotierzo claims the investment is driven by the need to "mitigate supply chain disruptions while improving agility and flexibility." Sounds like management-speak to me.

Before this shiny new kit, they say it took 21 hours to make 500 controllers; now, a mere 5 hours. That’s a substantial bump, if it holds in the real world.

The building where Delta Controls receives, manufactures, and ships all its products is now equipped with this upgraded assembly line. They’re keen to show it off, emphasising how the improvements enable them to "Do It Right and serve you even better as we continue navigating the new normal." Sounds good on paper, as marketing guff usually does.

According to Delta Controls, this is "just the first step of many ahead," suggesting further investment is coming. The focus, they say, is on addressing shareholder and customer expectations in the face of ongoing supply chain challenges.

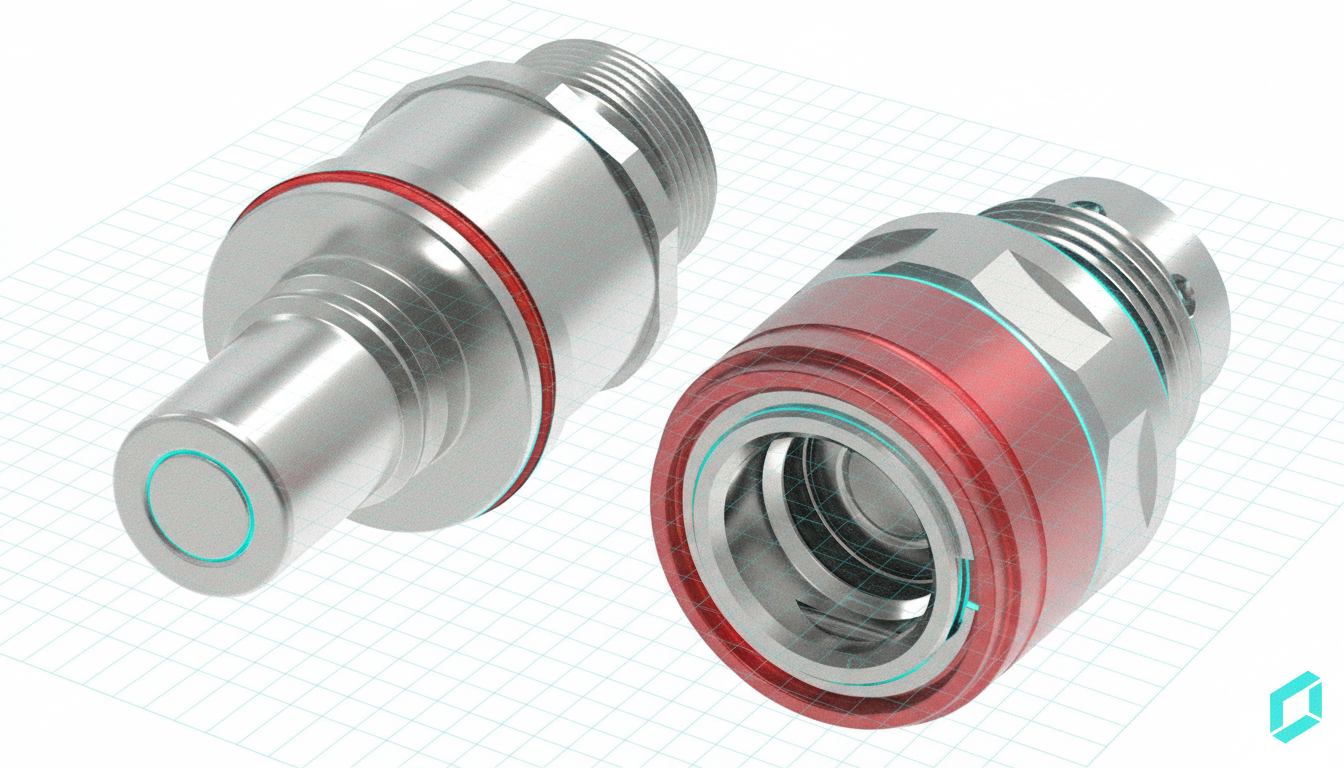

But here's the rub: will a faster assembly line actually make a difference to lead times? The bottleneck is rarely the board assembly itself.

Component sourcing and shipping often play a more significant role. So, while Delta Controls might be churning out boards at warp speed, customers may still be twiddling their thumbs waiting for the bits to arrive. See the original announcement.

One wonders if this investment will translate into tangible benefits, or if it’s just for show. Time will tell, I suppose.