Innocent Drinks' new carbon-neutral 'Blender' factory in the Netherlands relies on a Distech Controls system, installed by eco-i, to manage HVAC and contribute to its sustainability goals – but will it actually work?

The global drinks brand aims to change perceptions of factories with its new facility, boasting carbon neutrality through renewable energy sources.

eco-i, a system integrator, has installed an HVAC control system featuring Distech Controls products to ensure occupant comfort and energy efficiency, helping Innocent towards their carbon-neutral aspirations. But achieving true carbon neutrality is a tough ask for any manufacturing plant.

The new factory, dubbed 'The Blender', allows Innocent to manufacture its entire line of beverages under one roof, moving it closer to its goal of being carbon neutral by 2025.

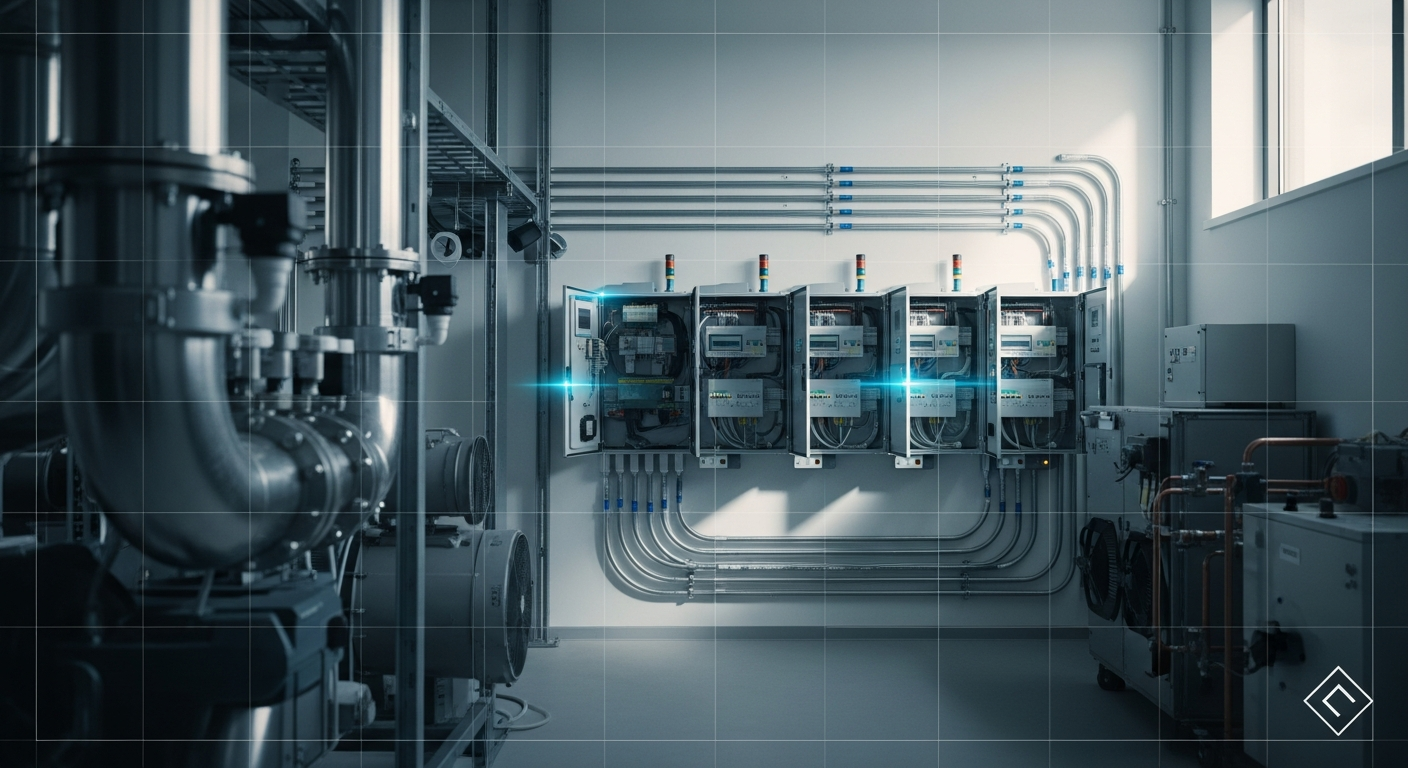

eco-i was tasked with designing and commissioning an HVAC control system for 12 air handling units and 85 fan coil units. These are connected to a site-wide smart building management system (BMS), linking HVAC, power, refrigeration, production and dispatch into a single platform.

According to Chris Roscoe, Sales Director at eco-i, 'The project had unique challenges,' thanks to Brexit and the pandemic. One hopes those challenges haven't compromised the final result.

Leveraging the BACnet communication protocol, the factory's BMS utilises the Distech Controls ECLYPSE Connected System Controller, ideal for central plant and mechanical equipment control. It’s modular, scalable, and offers up to 320 points.

eco-i also implemented the Distech Controls HORYZON-C interface for simplified commissioning, operations, and troubleshooting.

David Morrison, Operations Director at eco-i, noted the importance of rigorous testing: 'Ensuring rigorous testing was critical to delivering this project under these difficult conditions.'

Control panels were pre-commissioned with Wi-Fi access points and custom software, allowing remote air and water balancing without needing a BMS engineer on site. 85 Distech Controls ECY-PTU-208 controllers have been installed within the office space. Each model supports BACnet/IP communication and is listed as a BACnet Building Controller (B-BC).

Each control panel was provided with Wi-Fi access points and extensive software logic was created including web graphics to allow the air and water balancing to be completed on-site without the need for BMS engineer attendance.

The office fan coil units are further complemented by the elegant and intuitive Allure UNITOUCH™ room device that allows users to control temperature, lighting, fan speed and sunblinds from an attractive-looking device.

Let's hope Innocent’s new 'Blender' doesn't end up a right smoothie... *https://www.innocentdrinks.co.uk/a-bit-about-us/th...